Phone/Whatsapp: +86 19903886476

Email:zyunfei87@gmail.com

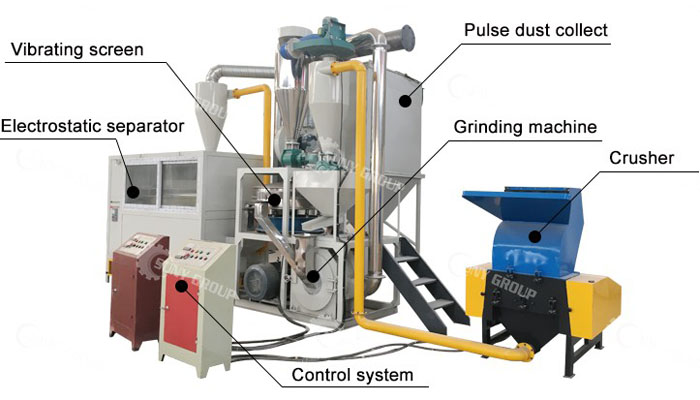

What is the process of aluminum-plastic crushing, sorting and recycling equipment?

The aluminum-plastic crushing, sorting and recycling equipment adopts the method of physical crushing and electrostatic sorting to separate the aluminum-plastic. First, the tablet is roughly crushed into flakes below 10mm by a knife-cutting crusher, and then enters a high-speed water-cooled turbo mill to finely crush the flakes. A mixture of aluminum and plastic is formed, and the materials that meet the requirements are screened by a rotary vibrating screen to separate aluminum and plastic by the principle of electrostatic separator.

The loss of both aluminum and plastic is very low, and the reuse rate of aluminum is close to 99%. The equipment adopts complete dry physical separation, which does not cause secondary environmental pollution and has good social and economic benefits.

Advantages of SUNY GROUP aluminum-plastic separation and recycling equipment aluminum-plastic board and tablet board processing equipment:

1. High automation program, simple operation and stable performance;

2. The separation efficiency of electric separation reaches 99%, and the finished product can be sold directly;

3. No waste water and waste gas discharge, real green sorting, no secondary pollution;

4. Low power consumption, low noise, small footprint and no dust pollution;

5. Wide range of sorting materials and fast sorting speed;

6. The aluminum-plastic sorting and recycling processing equipment adopts water-cooled and air-cooled turbine mills, which can separate the materials more cleanly and adapt to a wider variety of materials.